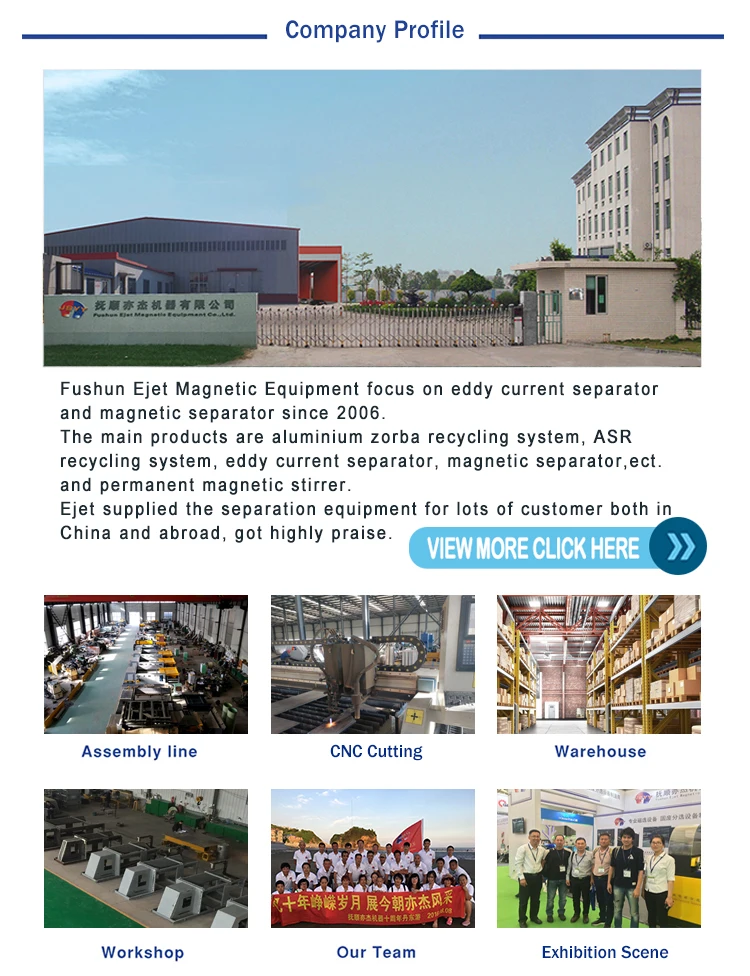

1. 13 Years Experience Focus On Magnetic Separator Manufacturing Since 2006.

2. Executive Chief Engineer Has 30 Years Experience.

3. Best Magnetic Material Supplier As The Magnetic Source To Ensure That The Demagnetization Rate Is Less Than 8% In 15 Years.

4. Our Main Components Are International Famous Brand Products.

5. The Magnetic Roller Is Tested For Air Tightness To Ensure That There Is No Water Or Iron Powder In The Magnetic System.

6. Quick Change Bearing Design, Convenient Bearing Quick And Easy Replacement

7. Customized Processing According To Customer Requirements.

EJET Eddy current separators, or non-ferrous separators, separate non-magnetic (non-ferrous) metals. They purify large bulk streams and/or separate non-ferrous metals for reuse. Eddy current separators have many uses. They can handle high capacities, because the conveyor belt separates and carries away non-ferrous metals continuously and fully automatically. An important factor for good separation is an even flow of material, supplied by a vibrating feeder or conveyor belt for example.

EJET separators are robustly built so they can remain operational day and night in even the most demanding applications, such as incinerator slag reprocessing. Application examples include:

1.Removal of aluminium caps for the glass recycling industry;

2.Removal of non-ferrous metals from slag from waste incineration plants;

3.Processing of scrap, electronics waste or household waste;

4.Elimination of impurities from recycled plastic streams for protection of injection moulding machines;

5.Recovery of casting residues in the metal casting industry.

And processing shredded scrap, demolition waste, packaging waste, aluminium salt slags, wood chips, glass or moulding sand.

|

Eddy Current Separator

|

|

Introduction:

|

High Quality Eddy Current Separator for Nonferrous from Garbage Separation

|

|

Parts:

|

Eddy Current Separator and Virbator Feeder

|

|

Production Capacity:

|

98.5% - 99.5%

|

Belt Width:

|

300mm

|

|

Long*Wide*High:(mm)

|

2080*1117*1285

|

Weight:

|

900kg

|

|

Warranty:

|

18 months

|

Rotor of Motor:

|

2.2kw

|

|

Feeding size:

|

≥3mm

|

Virbator Feeder of Motor:

|

0.12+0.12kw

|

|

Brand Name:

|

JSYY

|

Modle:

|

ECS-30P

|

|

Certification:

|

CE / SGS / ISO

|

Processing capacity: |

0-15ton/hour |

Our machine has been exported over 60 countries and Acquired unanimous praise from international friends

Our Service

1.We cooperate with superior suppliers.

2.The test of materials is free.

3.Strict quality checked for every machine before packing.

4.Engineers available to service machinery overseas.

5.Sales service support, also technology support.