Waste Incinerator Bottom ash (IBA) are the product of the waste-to-energy (WtE) process from the energetic usage of burnt solid waste in which municipal solid waste (MSW), Household Waste ,industrial or commercial waste and Medical waste from health-care facilities is burned to generate warmth and electricity for households and and Refuse-Derived Fuel(RDF) working site .

The production of bottom ash is rising because MSW is increasingly incinerated. Bottom ash is land filled in many countries.However, the material is suitable as a building material from a civil engineering viewpoint, e.g. for embankments and foundations of roads. Bottom ash contains a considerable amount of non-ferrous and ferrous metals that should be removed for such an application.

The Incinerator slags contain a particularly high proportion of recoverable metals such as ferrous metals , heavy copper , light aluminum .and a significant proportion of noble metals such as gold and silver are present in the <2 mm grain range.

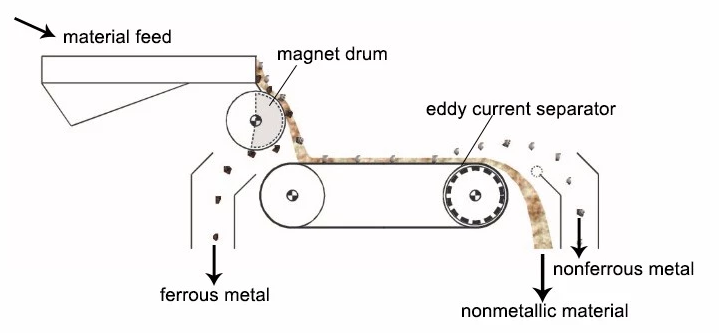

How to using magnetic and eddy-current technology to recovery ferrous , alloys copper aluminum non-ferrous metals, and stainless steel from the incineration bottom ash IBA

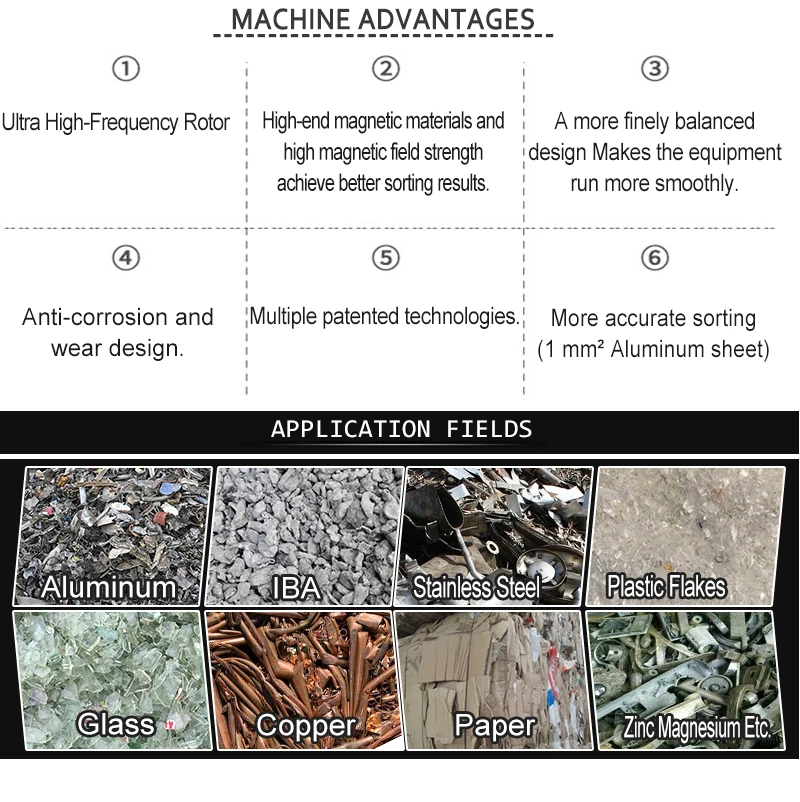

magnetic eddy current metals separation equipment /system provides best-in-class ferrous and non-ferrous recovery rates for shredding operations. widely used to achieve better recovery and a higher grade product, while delivering it at a lower cost per ton .

1.Drum magnets ,permanent or Electric Overband suspended magnets, magnetic pulleys for ferromagnetic metal recovery

2.Eccentric pole eddy current separators and Ultra-High-Frequency UHF Eddy Current Separator for alloys aluminum, copper nonferrous metal recovery , there also have two belt pass uhf Eddy Current Separator could be seleceted foroptimum micro-fine aluminum copper nonferrous particles sorting

3.Electromagnetic Induction Sensor Sorter for Stainless Steel sorting

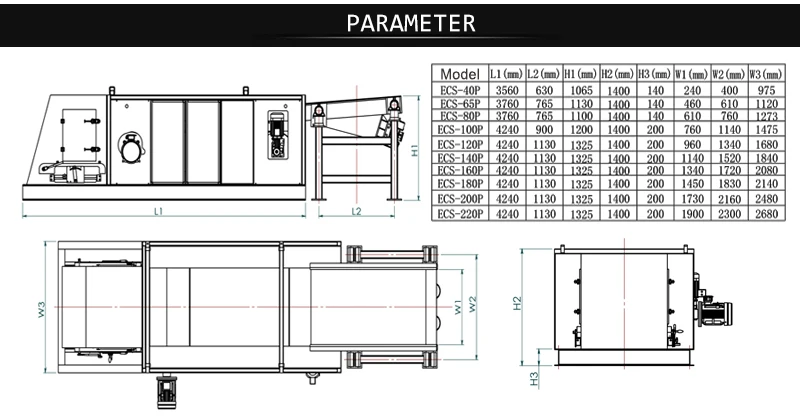

| Model |

Belt Width |

Belt Power |

Rotor Power |

Feeder Power |

Belt Speed |

Rotation Speed |

| ECS-40P |

450mm |

0.75Kw |

3Kw |

(0.12+0.12)Kw |

0-2m/s |

0-3000rpm |

| ECS-65P |

650mm |

1.5Kw |

4.0Kw |

(0.25+0.25)Kw |

0-2m/s |

0-3000rpm |

| ECS-80P |

800mm |

1.5Kw |

4.0Kw |

(0.25+0.25)Kw |

0-2m/s |

0-3000rpm |

| ECS-100P |

1000mm |

2.2Kw |

5.5Kw |

(0.55+0.55)Kw |

0-2m/s |

0-3000rpm |

| ECS-120P |

1200mm |

2.2Kw |

5.5Kw |

(0.55+0.55)Kw |

0-2m/s |

0-3000rpm |

| ECS-140P |

1400mm |

2.2Kw |

5.5Kw |

(0.75+0.75)Kw |

0-2m/s |

0-3000rpm |

| ECS-160P |

1600mm |

2.2Kw |

5.5Kw |

(0.75+0.75)Kw |

0-2m/s |

0-3000rpm |

| ECS-180P |

1800mm |

2.2Kw |

5.5Kw |

(0.75+0.75)Kw |

0-2m/s |

0-3000rpm |

| ECS-200P |

2000mm |

2.2Kw |

5.5Kw |

(0.75+0.75)Kw |

0-2m/s |

0-3000rpm |

| ECS-220P |

2200mm |

2.2Kw |

5.5Kw |

(1.1+1.1)Kw |

0-2m/s |

0-3000rpm |

Other APPLICATION AREAS of magnetic eddy current metal sorting system

OTHER INDUSTRIAL MAGNET INDUSTRIES SERVED

1.AUTOMOBILE SHREDDING & SCRAP METAL PROCESSING,such as Car bodies ,Mixed scrap,Aluminum Can Recycling 2.ADVANCED METAL Automotive white goods RECOVERY & SORTING ,such as Engine blocks ,Aluminium rims and

profiles ,etc ALUMINUM /alumina SHREDDING & SORTING

3.WASTE TO ENERGY Power Plants for maximizing metal extraction from the incineration bottom ash

4.MUNICIPAL SOLID WASTE RECYCLING

5.scraps Electric and Electronic Equipment (WEEEs) e waste RECYCLING

6.ferromagnetic and Non-ferrous metals recycling in steel mills and foundries Applications

7.Food, Chemical, Pharmaceuticals

8.Lumber/ Waste wood processing

9. Mining/Minerals

10.Quarry/Aggregate

------------------------------------------------------------------------------------

1. What is the MOQ of your machine?

A: Our MOQ is 1 set

2. How long is the machine warranty period?

A: the product warranty period is 12 months

3.What kind of metal is eddy current applied to?

A:Eddy Current Separator suitable for aluminum, copper, brass.etc non-ferrous scraps separation from non - metal materials of size >3mm.

4.Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition , size ,handling capacity and expected separation result .

5.What are the pros and cons between a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much suitable for complicated material situation , The eccentric rotor design reduces long-term wear due to heated ferrous build up ,can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence , the concentric type have a little bit better separation effect,but must make sure no ferrous exist.

More details , please kindly contact :

Mob/Wechat/WhatsAPP: +86 15242300557

Email:jasmine@sino-magnets.com.cn