Metal contaminants in plastics (e.g. PET PP PA POM ABS HDPE PVC UPVC)or rubber often lead to production stops and loss of quality. It can also cause damage to injection moulding machines, extruders, calenders, mixers, grinders and other equipment. Moulds, dies and other machine parts can also be damaged by metal contamination .

FUSHUN EJET offers a wide variety of the most powerful Rare Earth Magnetic Separators for the plastics industry... ranging from grate magnets to powerful Permanent or Electromagnetic separators to capture and hold fine ferrous and weakly magnetic stainless steel to increase product purity and process up time. and EDDY CURRENT SEPARATOR- NonFerrous Separator for precious removes aluminum, brass, copper from post consumer plastic bottles and PET flake to recover extremely high purity plastic with up to 99% good product yield .

Mainly operation to removal harmful Metal in Plastic Waste

First Stage :Before Shredder / Grinders

Early in the process, ferrous and non-ferrous metal contamination is removed from the waste plastic using Magnetic Separators and Eddy Current Separators. Initially, after the plastic is released from the compacted bale, the waste is fed into a primary shredder. To protect the shredder from damage .

At this stage, the type of ferrous metal contamination found in the plastic is diverse and often surprising. It can include metal packaging miss-sorted at the MRF, heavy lumps of iron that increase the weight of the plastic bale, and metal picked up during transportation. There have even been reports of car engine blocks. Reasonably sized items of cast iron entering the shredder will cause significant and costly damage and result in the plant being closed until a repair is possible.

|

Ferrous Material Removal

By Drum/ overband Magnetic Separation machine

|

Non-ferrous Scraps removal

By Eccentric Pole Eddy Current Separator

|

|

|

|

Magnetic drum In-housing, a wide variety of powerful Rare Earth Magnetic Separators to capture and hold ferrous and weakly magnetic stainless steel from the mixture

Overhand suspension magnets often working together with a permanent magnetic pulley unit and the robust magnetic drums offer the highest separation efficiency along with outstanding functionality and robustness.

|

Eccentric Pole Eddy Current Separator offer good performance on aluminium recycling solutions .Typical input aluminum is: soft and hard aluminium material, clean as well as contaminated material, sheets, blanks, profiles, litho, castings, turnings, foils, Used Beverage Cans (UBC), ”old rolled aluminium” etc. |

Second Stage : before Injection Moulding Machines, Extruders, Calenders, Mixers

After the primary shredder, the waste plastic has been reduced in size and many contaminants liberated. This shredded waste plastic is fed onto another Magnetic Separator, commonly a Drum Magnet or Pulley Magnet, to remove liberated smaller ferrous metals.

The type of ferrous metal separated at this stage includes steel spanners, nuts, bolts, screws, fine metal wires, springs, iron shards, fine ferrous dust, and chunks of stainless steel. Most of the ferrous metal was not part of the original plastic packaging and has been introduced between disposal and processing.

The cleansed plastic waste then passes over a high intensity concentric Eddy Current Separator to remove fine non-ferrous metals. Commonly separated metals include aluminium beverage cans, foils, tubes, and even window frames.

After the metal contamination has been removed, the plastic waste moves to the next stage in the plant, which could be further separation of contamination or sorting by colour or plastic type.

| Stainless Steel & Weakly Magnetic metal |

Fine Non-ferrous & Copper Bare Electric Wire |

|

|

|

Powerful Grate magnet protection against fine and tramp iron contamination. simple installation in

various shaped hoppers, floor openings, chutes and ducts Ideal for food, grain separation, also used in recycling oil, plastics, minining, etc

High Intensity magnetic Separation Conveyor incorporates extremely high gauss fields, neodymium rare earth magnets to hold and extract paramagnetic work-hardened 300 stainless steel metal and and Wire-Cleaning Applications from the product stream

|

Ultra High-Frequency UHF Eddy Current Separator to recovers non-ferrous fines and bare ALUMINUM COPPER wire

FINES Metallic material removes by High-Frequency EddyC in consumer polymer plastic PET bottles flake rubber regrind recycling

|

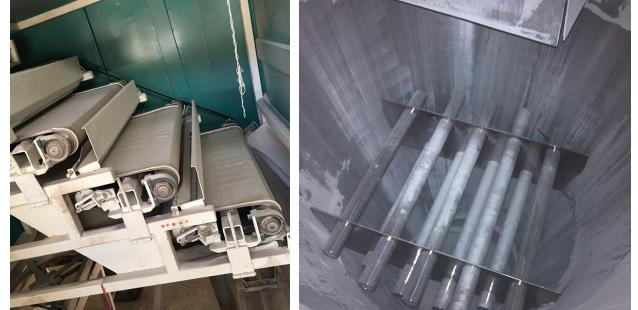

working site in plastic recycling for reference

Beside the plastic reycling industry ,Magnetic metal sorting system is also widely used in all kinds of wastestream Recycling and Recovery Facility.environmental protection industries, like waste classification, waste electrical and electronic equipments recycle, and the treatment of non-ferrous metal industrial materials.MagneticEddy Current Separator uses a strong magnetic field to efficiently & accurately repel aluminum ,copper ,Zinc ,Magnesium etc non-ferrrous from incoming materials, recovering your highest value product at high levels of purity.

Other application of eddy current magnetic metal separation system :

1.Recovery of ferrous , Alloys Aluminum Copper non-ferrous , stainless steel valuable metals from waste materials.

Shredded End-of-Life vehicle/cars (ELVs) & auto shredder residue(ASR)recycling industry

shredded End-of-Life domestic application

shredded and pre-treated co-mingle recyclables metal (Zorba) recycling industry

Slag Ash after the incineration of in municipal waste-to-energy .

Metallurgy steel or Aluminum Zinc nonferrous alloys slag scraps recycling industry and aluminum-shell-sand recycling lines.

Waste Electrical and Electronic Equipment(WEEE waste) recycling plants

Crushed waste electrolytic capacitors

Shredded aluminum sheets tubes profiles Taint tamor TT scraps purify or upgrade

2.Separation of various ferrous , aluminum ,copper non-ferrous metallic impurities from recyclable materials.

Crushed glass cullet recycling Industry

PP PET PVC ABS UPVC HDPE plastic recycling industry .

non-ferrous copper aluminum brass rivets and hinges separation in wooden timber recycling industry.

Non-ferrous scraps separation from crushed rubber .

Aluminum cans sorting from municipal solid waste

About Fushun Ejet

This was in 2004, when our founder, Bingxun Wang, first used the magnetism knowledge to make research and designed the first set eccentric pole eddy current separator in China. Thus we are fully aware of this responsibility in sorting resources field for nonferrous metal.

In the year 2006, with 25 years magnetic experience Ejet Magnet Established, Keeping improvement for all kinds of magnetic separators, to provide high quality and high performance products is our own responsibility, moreover, to offer the best solution and the most effective service is one of higher-standard targets we are pursuing. Ejet has strict quality control system for raw materials inspection, producing quality inspection and machine testing.

With 4 members team in the beginning, Ejet has grown through continuous product innovation and worldwide expansion to over a 5000 square feet of manufacturing space and more than 100 employees.

The main products eddy current separator , magnetic separator, induction sorters and AI technology machine for recycling industries had been export to more than 50 countries.

Materials testing and machines OEM could be available for better solutions of metal recycling, plastic, glass cullet, construction waste, incineration bottom ash, Aluminum, E waste recycling. Also for food, chemical, lithium batteryindustries.

Ejet after sales service promise that within 15miniutes we will make response to customer’s consolations. On condition that some problems cannot be solved by calls or call videos, engineers are available to serve overseas.

FAQ

Q:What kind of metal is eddy current applied to?

A:Eddy Current Separator suitable for aluminum, copper, brass.etc non-ferrous scraps separation from non - metal materials of size >3mm.

Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model, please let us know the material`s situation .including the composition , size ,handling capacity and expected separation result

Q:What are the pros and cons between a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much suitable for complicated material situation , The eccentric rotor design reduces long-term wear due to heated ferrous build up ,can effectively avoid the device damage caused by impurity ferrous metal.

More details , please kindly contact :

WhatsApp/Wechat/Line: +86 15242300557

Email:jasmine@sino-magnets.com.cn