Modern metal Separation Equipment such as magnetic separators, eddy current separators and sensor sorter offering complete material recovery facilities(MRF) and municipal solid waste (MSW) to effectively separate valuable ferrous , alloy copper brass aluminum nonferrous and stainless steel metals .

these waste also referred to as commercial waste, industrial waste and household trash waste, consists of everyday items like glass, plastics, metals, textiles, organics, and paper discarded by the modern society. This composition contains a large portion of valuable products, compost and high calorific materials (refuse-derived fuel (RDF)) that, once extracted by mechanical treatment or degraded by biological treatment, offers a wide range of new resources.

Process for valuable metal recovery from various trash via magnertic technology

The metal fraction consists valuable Metal source , both Ferrous & copper brass aluminum Non-Ferrous and stainless steel Metals included in , and these metal could get cost-effctivity recovery via various magnetic separation machine

1.Permanent & Electric magnetic Separation deviced could be selected for ferromagnetic separation & Recovery

Drum Magnetic Separation devices

| Electro or permanent Magnetic Drum much suita for heavy-duty, high-volume ferrous separators typically used in ASR/MSW/MRF for metals recycling and recovery. |

This Magnetic Pulleys replaces the head pulley on a conveyor, attracting and holding the ferrous metal to the belt achieving very effective separation.

|

|

|

Overbelt Magnetic Separator

|

The Suspended Electromagnet mounted or suspended over a conveyor belt to remove large pieces of tramp metal from conveyed materials.

|

permanent magnetic pulley, and self-cleaning overhead suspension magnets unit and the robust magnetic drums offer the highest separation efficiency along with outstanding functionality and robustness. |

|

|

2.powerful Eddy Current Separator for recoverable non-ferrous metals such as aluminum beverage cans copper content, zinc plate, brass non-ferrous metallic sorting .

3.Stainless steel recovery

Electromagnetic sensor sorting units base on the adjusted variably and precisely for the optimum product generation are outstanding separation of stainless steel from ASR/MSW/MRF

Company Profile

This was in 2004, when our founder, Bingxun Wang, first used the magnetism knowledge to make research and designed the first set eccentric pole eddy current separator in China. Thus we are fully aware of this responsibility in sorting resources field for nonferrous metal.

In the year 2006, with 25 years magnetic experience Ejet Magnet Established, Keeping improvement for all kinds of magnetic separators, to provide high quality and high performance products is our own responsibility, moreover, to offer the best solution and the most effective service is one of higher-standard targets we are pursuing. Ejet has strict quality control system for raw materials inspection, producing quality inspection and machine testing.

With 4 members team in the beginning, Ejet has grown through continuous product innovation and worldwide expansion to over a 5000 square feet of manufacturing space and more than 100 employees.

The main products eddy current separator , magnetic separator, induction sorters and AI technology machine for recycling industries had been export to more than 50 countries.

Materials testing and machines OEM could be available for better solutions of metal recycling, plastic, glass cullet, construction waste, incineration bottom ash, Aluminum, E waste recycling. Also for food, chemical, lithium batteryindustries.

Ejet after sales service promise that within 15miniutes we will make response to customer’s consolations. On condition that some problems cannot be solved by calls or call videos, engineers are available to serve overseas.

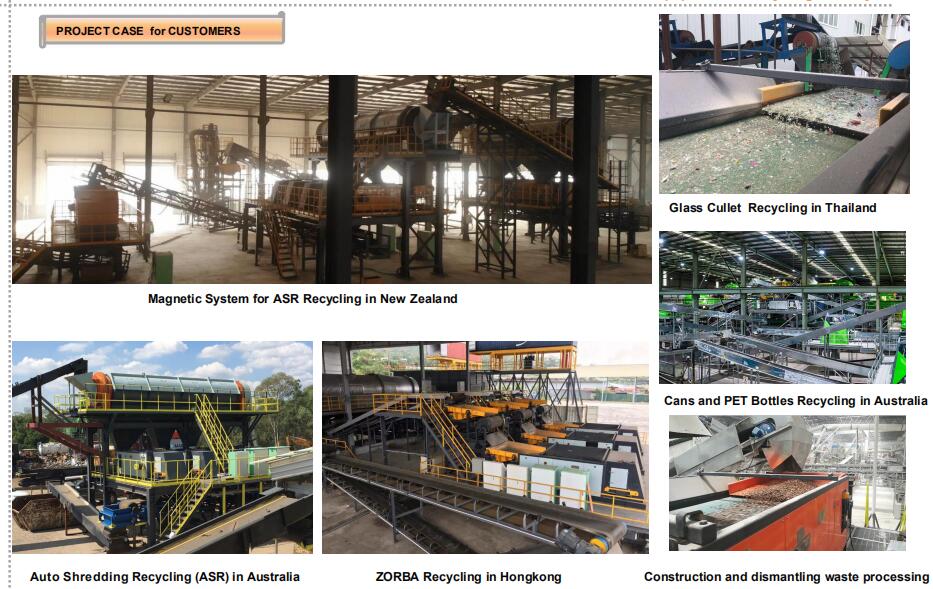

Other Working Site of Magnetic technology for various Metal Solution in Recycling Industry

End-of-Life Vehicle (ELVs) Automobile Shredding &Scrap Metal Processing

Auto Shredding Residue (ASR)

In plastics processing and recycling industries

Glass Recycling Industry

Municiple Solid Waste (MSW) Process

Incineration Bottom ash processing in WASTE TO ENERGY Power Plants

Mixed metal scraps recycling industry

Used Beverage Cans (UBC) Recycling industry

Ferrous and Non-ferrous Alloy upgrading in foundries Applications

Lumber & Waste wood processing

E-SCRAP (WEEE ) waste Recycling

In Construction and Demolition waste for maximum metal recovery

FAQ

1.Q:are you Original Manufacturer ?

A:Yes

2.Q: Which machine /system should I choice for ?

A:To guarantee the good performance , please kindly provide as details information as possible about the material ,

e.g. where is the material come from ? whats the main components and the percentage ?size range , productivity