Eddy current separator with concentric pole system separates aluminum parts(Al-cans)

Product Description

An Eddy current magnetic actually repel the non-ferrous metals, such as aluminium caps and rings from PET bottles, Auto and white goods separation, fluff from metal fragmentation processing can be run over an eddy current, which will pull out non-ferrous material. Shredded computer items can be run over for aluminium, gold, and silver (if the precious metal isn’t held down in other components). Wood waste can contain stainless steel and aluminium conduits and medical waste and other electrical components. Eddy current magnetic will throw this material from the rest of the scrap from which it is being separated.

Standard Features and Benefits for nonferrous metal Extraction equipment:

1. Designed with top grade NdFeB or permanent rare earth magnet material , having high-strength magnetic field and long life

2.Non-ferrous metal recovery in refuse streams and ash streams in Waste-to-Energy facilities,can up 98% recovery rate of aluminum cans from commingled recyclables

3.Import main parts:Nord Gear Motor,NSK Bearing,Seigling Belt,Schneider Electric

4.Rugged heavy-duty construction effectivily reduce belt long-term wear.

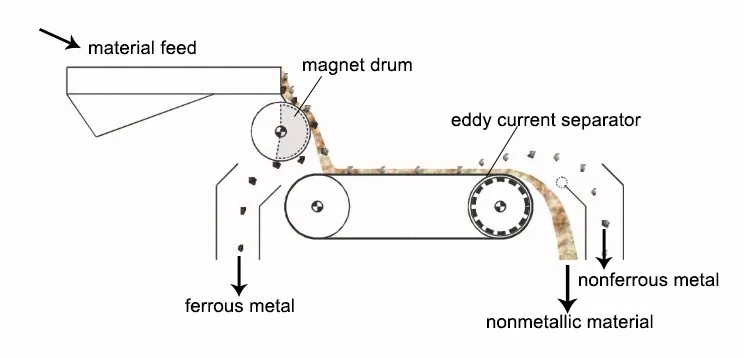

Working principle

When a piece of non-ferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed. This forms eddy currents in the aluminum which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the nonmetallics, allowing the two material streams to be separated.

Important: When looking at an Eddy current separator, the waste travelling over the magnetic must be in a thin layer to allow the magnetic perform to its best, in case processed metal waste is mixed with ferrous metal. The Ideal format for any metal separation is first magnetic ferrous discharge, onto a vibration conveyor to spread out and further separate the remaining metals to allow the Eddy current magnetic to work at its optimal efficiency.

Also Particle size can matter, since the eddy current depends on surface area. Pieces of scrap that are a half-inch in size or larger work best.

Specification

|

Model

|

Belt Width

|

Motor Power

|

Dimension (mm)

|

Weight

|

|

mm

|

Kw

|

Length

|

Width

|

High

|

Kg

|

|

ECS-40

|

450

|

3.0/0.75

|

2080

|

1357

|

1100

|

1100

|

|

ECS-65

|

650

|

4.0/1.5

|

3300

|

1500

|

1200

|

1200

|

|

ECS-80

|

800

|

5.5/1.5

|

3300

|

1700

|

1200

|

1400

|

|

ECS-100

|

1000

|

5.5/1.5

|

3300

|

1900

|

1200

|

1600

|

|

ECS-120

|

1200

|

5.5/2.2

|

3300

|

2000

|

1200

|

1800

|

|

ECS-140

|

1400

|

7.5/2.2

|

3620

|

2130

|

1587

|

2100

|

|

ECS-150

|

1500

|

7.5/2.2

|

3420

|

2240

|

1530

|

2200

|

|

ECS-180

|

1800

|

7.5/2.2

|

3300

|

2700

|

1200

|

2800

|

Application for concentric pole system separators

Separate aluminum,Stainless steel, copper, brass metals from shredder residue and fluff, wildy used in municipal recycling facility (MRF) municipal solid waste facility (MSW), scrap residue and other recyclables(auto shredding residue operations, glass cullet, electronic scrap, UBC reclamation, etc)

eddy current separation equipment in PET flakes recycling eddy current separator in refrigerator dismantling recycling

eddy current sorting machine in steel slag sorting nonferrous separation machine in aluminum recycling

Packaging & Shipping for eddy current separation equipment

« Other product as a professional magnetic equipment supplier

1.eddy current separator for aluminum /copper or other nonferous metal removal or collection .

2.wet type magentic separator for beneficiation mineral slurry

3.dry type magnetic separator for dry powder or granular material

4.suspension magnetic separator ,Divided into permanent magnet and electromagnetic

and various other magnetic equipement as clients needs .

Most suitable machine would be recomended to you according to your informations.

Any requirement Please Contact Miss Jasmine Song :

Email: jsyy@sino-magnets .com.cn

Mobile: 86 15242300557

WhatsApp: 86 15242300557

Skype: luckjasmine86

Wechat: 86 15242300557

QQ: 377375411